Marine Mooring Solutions – Premium Chocks & Pipes for Safe Vessel Mooring

Complete Mooring System Components for Professional Operations

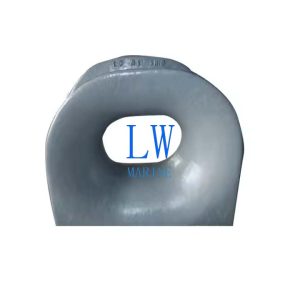

Our marine mooring chocks and JIS F2030-1978 Mooring Pipes form essential parts of a reliable mooring setup, designed to protect ropes and ensure secure vessel anchoring. These heavy-duty components are classification society approved and engineered for long-term performance in harsh marine environments.

Key Products & Benefits

✔ Standard Mooring Chocks

-

Positioned between bitts and bollards

-

Reduce rope friction by up to 50%

-

ABS, DNV, LR, BV, GL certified

✔ Single Point Mooring Pipes (Type A/B)

-

Type A: General temporary mooring

-

Type B: Welded at vessel bow for permanent installation

-

Primed or galvanized for corrosion resistance

-

Prevents mooring line wear at bulwarks

✔ JIS F2030-1978 Compliance

-

Precision-engineered for large vessels

-

Installed below gunwale for optimal protection

-

ZG200-400/ZG230-450 cast steel construction

Technical Specifications

| Component | Features |

|---|---|

| Mooring Chocks | Standard setup between bitts/bollards |

| Mooring Pipes | Type A (temporary) / Type B (welded) |

| Material | ZG200-400 / ZG230-450 Cast Steel |

| Finish | Primed Paint or Galvanized |

| Standard | JIS F2030-1978 |

| Approvals | ABS, DNV, LR, BV, GL |

Parameters:

| Nominal Size | Unit:mm | |||||||||||

| Calculated mass (kg) | L | L1 | L2 | H | H1 | H2 | B | R | R1 | T | C | |

| 400 | 210 | 400 | 780 | 570 | 300 | 680 | 460 | 350 | 150 | 210 | 35 | 65 |

| 500 | 340 | 500 | 940 | 690 | 400 | 840 | 580 | 400 | 200 | 240 | 40 | 70 |

| 600 | 490 | 600 | 1100 | 810 | 450 | 950 | 655 | 450 | 225 | 270 | 45 | 75 |

| 700 | 660 | 700 | 1260 | 930 | 500 | 1060 | 730 | 500 | 250 | 300 | 50 | 80 |

| 800 | 880 | 800 | 1420 | 1050 | 600 | 1220 | 850 | 550 | 300 | 330 | 55 | 85 |

The description/sizes may be different with goods, please check with us when order.

Tag: Our other products

Click here to contact us via whatsapp