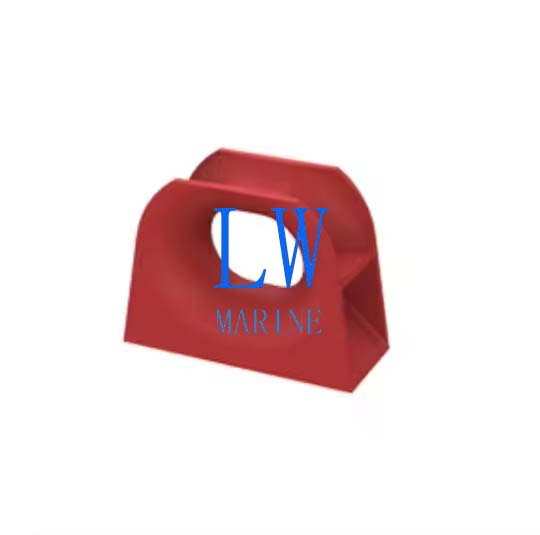

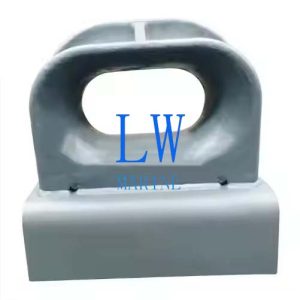

Marine Closed Chocks

Our Marine Closed Chocks are robust, heavy – duty cast steel solution meticulously engineered to expertly guide and shield mooring ropes from excessive wear and tear. As indispensable components in the maritime industry, these chocks play a pivotal role in ensuring the safe mooring of vessels across all types of marine environments, from calm harbors to rough seas.

Key Features & Significant Benefits

Unparalleled Rope Protection

- Slippage Prevention: The closed – design structure of our chocks effectively prevents rope slippage, ensuring that the mooring ropes stay firmly in place during the mooring process. This reduces the risk of accidents caused by loose ropes and enhances overall mooring safety.

- Friction Reduction: By minimizing friction between the rope and the chock, our product can reduce friction – related damage to the mooring ropes by up to an impressive 60%. This significant reduction in friction extends the service life of the ropes, saving costs on frequent rope replacements.

- Long – Lasting Rope Performance: With reduced wear and tear, the mooring ropes can maintain their strength and integrity for a much longer period. This means that vessels can rely on their mooring ropes for extended use without compromising safety.

Strict Industry Standard Compliance

- Multiple Standard Versions: Our Marine Closed Chock is available in both ISO 13729 and JIS F2005 – 75 versions, meeting the requirements of different international maritime standards. This ensures that our products can be seamlessly integrated into various marine systems worldwide.

- Interchangeability: These chocks are interchangeable with major international standards, providing flexibility for shipbuilders and operators. Whether you are working on a new vessel construction or a retrofitting project, our chocks can fit into your existing mooring systems without any compatibility issues.

- Certified Quality: Our products are certified for commercial marine use, guaranteeing that they meet the highest quality and safety standards. This certification gives customers peace of mind, knowing that they are using reliable and trustworthy components for their vessel mooring.

Comprehensive Chock Solutions

- Diverse Product Range: In addition to our high – quality Marine Closed Chocks, we also supply Open Chocks and Special Chocks to meet different mooring requirements. Whether you need a chock for a specific application or a unique vessel design, we have the right solution for you.

- Custom Design Services: We offer custom designs upon request, allowing customers to tailor the chocks to their specific needs. Our expert engineering team can work closely with you to develop a chock that fits your vessel’s dimensions, mooring system, and operational requirements.

- Full Size Range: We provide a full range of sizes to accommodate all types of vessels, from small fishing boats to large cargo ships. This ensures that every vessel can find the perfect chock to ensure safe and efficient mooring.

Durable and Low – Maintenance Construction

- High – Grade Material: Made from high – grade marine cast steel, our chocks offer maximum strength and durability. They can withstand the harsh marine environment, including strong waves, high winds, and saltwater corrosion, without compromising their performance.

- Corrosion – Resistant Coatings: Our chocks are coated with special marine coatings that provide excellent protection against corrosion. This extends the service life of the chocks, reducing the need for frequent maintenance and replacement.

- Minimal Maintenance Requirements: Due to their durable construction and corrosion – resistant properties, our chocks require minimal maintenance. This saves time and costs for ship operators, allowing them to focus on other important aspects of vessel management.

Technical Specifications

| Feature | Specification |

|---|---|

| Type | Closed Chock |

| Material | Marine Cast Steel |

| Standards | ISO 13729, JIS F2005 – 75 |

| Surface | Protective Coating |

| Standard & Nominal Size | – CB T34 – 2007 Mooring Chock: Type A and AF range from 150 – 550mm, Type B and BF range from 100 – 550mm, Type C ranges from 120 – 320mm – DIN 81915 Chock: Type A has a capacity of 1 – 32T, Type B 1 – 8T, Type C 20 – 32T, Type D 1 – 8T, Type E 8 – 20T – JIS F 2030 – 1978 Single Point Mooring Pipe: Type A and Type B measure 400x300mm – 800x600mm – JISF 2007 – 1976 Mooring Chock: Type A ranges from 150x110mm – 500x250mm, Type B ranges from 150 – 300mm – NS 2590 Mooring Chock: Available in 300x250mm and 400x250mm – NS 2589 Mooring Chock: Type A and Type B come in 300x250mm and 400x250mm – Panama Chock: – – GB 11586 – 89 Panama Chock: Type AC ranges from 310 – 500mm, Type AP ranges from 310 – 360mm, Type BC ranges from 310 – 500mm, Type BP ranges from 310 – 360mm – ISO 13729 – 2012 Closed Chock: Type A and Type B measure 250x200x214 – 500x400x525B – EU Type Deck Mounted Chock: Ranges from 315x250mm – 800x600mm – EU Type Bulwark Mounted Chock: Ranges from 315x250mm – 600x450mm – ISO13728 Panama Chock: Type A and Type B are 310mm and 360mm – JIS F 2005 – 1975 Closed Chock: Length (L) ranges from 100mm – 500mm – JIS F2017 Type AC Panama Chock: L ranges from 310mm – 500mm – JIS F2017 Type AP Panama Chock: L is 310mm and 360mm – JIS F2017 Type BC Panama Chock: L ranges from 310mm – 500mm – JIS F2017 Type BP Panama Chock: L is 310mm and 360mm |

Attention please: The description was copied from different cooperating manufacturers. The description may be different with the goods, please check with us when order.

Tag: Our other products

Click here to contact us via whatsapp